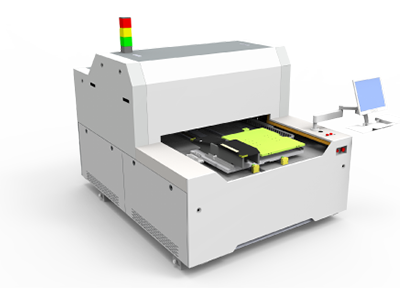

3D Exposure Machine Core Technology

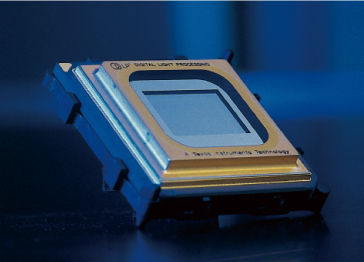

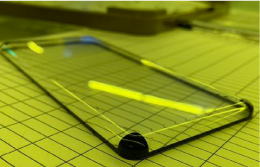

Digital Imaging Technology

Use TI Pattern Generator-DMD chip to produce digital image. DMD is composed of 800,000 or 2,000,000 micromirrors. Square mesh points can be presented clearly and sharply within the scope of DMD light spots. This latest digital exposure system has become a new industry standard.

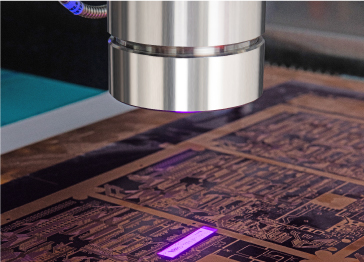

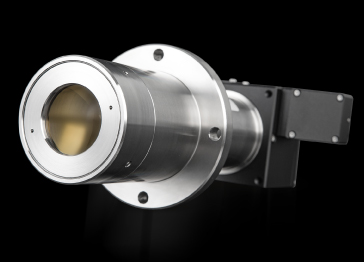

375 Nanolaser

Industrial-grade 375 nm coupled laser, Independently research-and-developed laser imaging system increases laser utilization of 375 nm coupled laser from traditional 30% to 50%

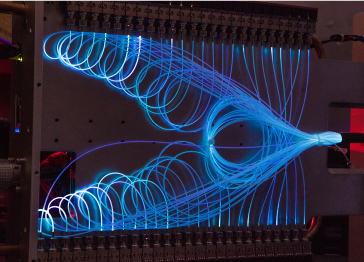

High Precision Optical Engine

DPL (Digital light processing) optical system uses UV laser light source, The output laser achieves high high uniform illumination of DMD through a special collimating lens, and finally outputs the patterns through projection lens. Projection lens is a double telecentric lens using special ultraviolet optical material with characteristics of low distortion and high transmittance.

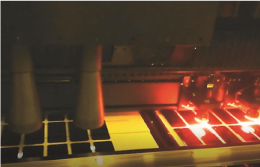

High Precision Motion Platform

±1μm motion control system; real-time motion error compensation system