- Industry Solutions

- Technology & Products

- Service & Support

- News

- About Us

- Qualification & Honor

- Contact Us

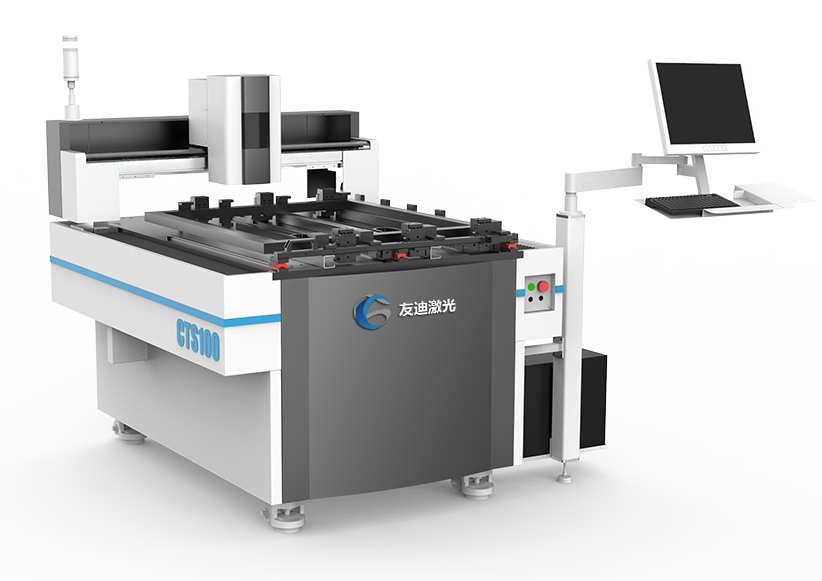

High Precision:

Resolutions 1270dpi or 2540dpi, with raster 133lpi/dpi (halftones printing)

High Efficiency:

3 minutes to finish the exposure on screen size 1000mm*1000mm. Stencil making efficieny has been greatly improved due to a lot of time is saved by the accurate exposure alignment and lobor reduction

Low Cost:

Elimination of film positives. Litho film are becoming increasingly expensive and the number of suppliers on the maket is rapidly decreasing. 1 procedure of CTS digital screen making to replace 5 procedures of from the conventional process

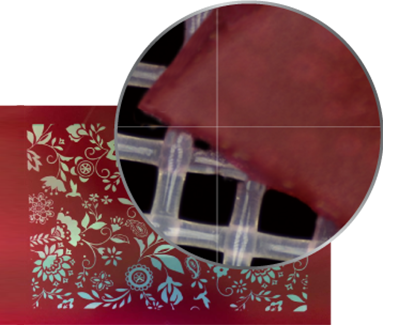

160um/ 147 times/QTX/270ma100mm/s

20um/10times/LX 660-B/250mA100mm/s

8um/147 times/LX660-B/260mA40mm/s

20um/60times/Trifecta/165mA200mm/s

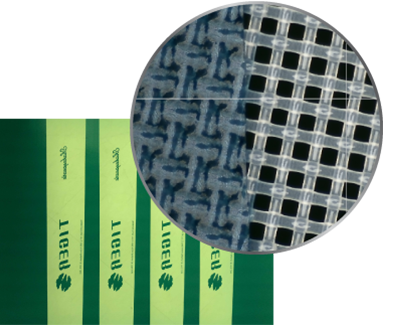

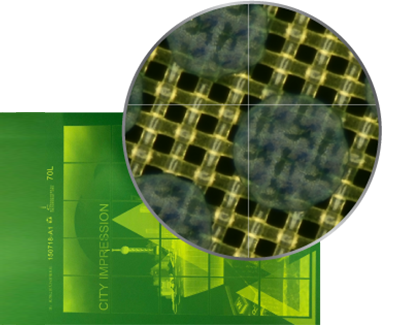

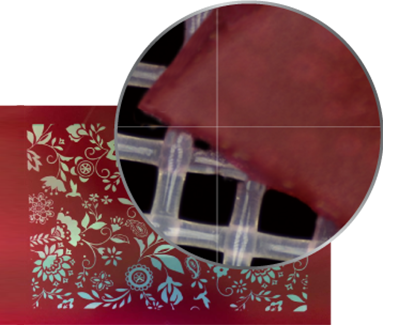

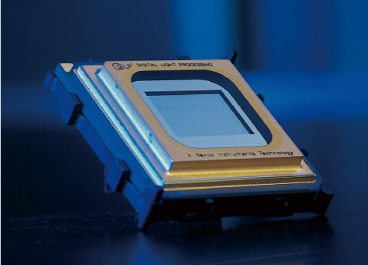

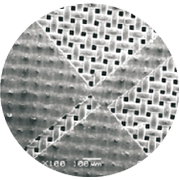

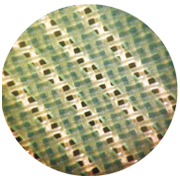

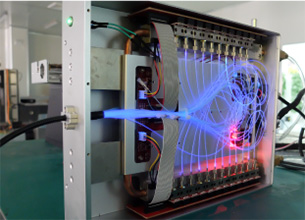

Digital images are produced by DMD (digital micro-mirror device) which has over 800 thousand or 2 million micrometer micro-mirrors, enabling clear and sharp squre dots. This latest digital exposure system has now become the new standards for screen printing industry.

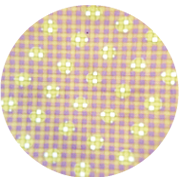

It is easy and fast to achieve raster 133LPI and high quality screen dots by the optical 1270dpi, while with the opitcal 2540dpi, high definition curved lines and perfect FM screen dots can be realized.

2540dpi

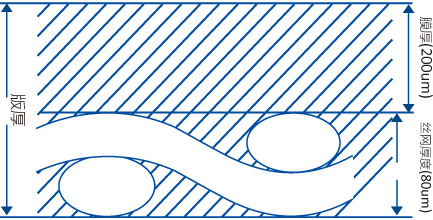

线条宽度 50um

5% 网点

四色网图片

Exellent laser piercing power, 15W, 20W and 25W three laser powers are optional, and the thickness EOM 120μm with solvent resistant emulsion and EOM 220μm with water resistant emulsion can be achieved for some special screen making such as carbon oil and capillary.

Data files is directly read by the CTS and then convented into images which will be transmitted through laser beams onto screens by DMD and lens.

| Specification / Model |

CTS100

CTS160V

|

|---|---|

| Application | Textile, decals, labels, decorations, etc. |

| Max screen size ( mm ) | 900x1000 |

| Min screen size ( mm ) | 400×400 |

| Max exposure size ( mm ) | 800x900 |

|

Screen frame thickness (bespoke service is available) |

25-40mm |

| Imaging System |

DMD DLP Technology

Close-packed Technique

|

| Emulsion thickness (EOM) | Solvent resistant emulsion 3μm-150μm, water resistant emulsion 3μm-220μm |

| Exposure time | 120-240s / M 2, 350 mesh yellow screen, (SBQ type photosensitive emulsion) |

| Resolution |

1270dpi

720dpi/1440dpi

|

| Raster | 133LPI |

| Focus system | 1_bit tiff |

| File format | UVLD laser,wavelength 405±5nm |

| Laser type |

15W/20W(Optional)

64、96、128(Optional)

|

| Laser power | 1600x1350x1550 |

| Equipment size (mm) | 1200KG |

| Equipment net weight |

Yellow light room with cleanliness Class 10000, temperature 22±2°C, 40-70% relative humidity (No condensation) |

| Conditions | Single phase 220v, 50/60HZ, 4KW(CTS200,CTS300), 5KW(CTS500,CTS700), gas 1L/min |

*Specifications subject to change without notice

Jiangsu GIS Laser Technologies Inc.